Make Valentine’s Day 2026 Memorable on the South Shore with Help from Merry Maids

February 12, 2026Best DEX for AI Agents in 2026 – Exploring Dark Pool Trading with Quote.trade

February 12, 2026

Introduction

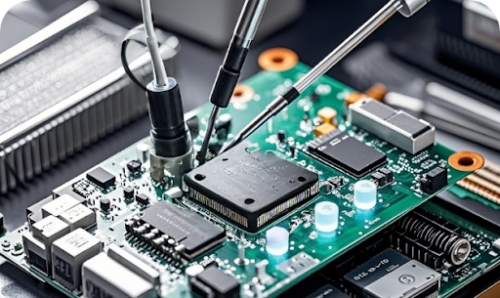

High frequency electronics are increasingly valuable in today’s digital world. From smartphones and medical devices to satellites and 5G networks, many of today’s systems rely on fast, steady signals. HERE high-frequency PCB technology comes into play. These custom circuit boards are made specifically for high speed signal integrity, and have extremely low loss and very high accuracy. But they are far from easy to create. It demands sophisticated device, talented engineers and strict quality control. Ellen Reeth: Many corporations fail to meet these criteria. That is where FastTurn PCBs shine. FastTurn PCB is experienced and uses cutting-edge techniques to provide high quality, reliable products. In today’s post, we’ll discuss how high-frequency PCBs are manufactured through to why customers trust us with their work.

Understanding High-Frequency PCB Technology

A HF PCB is not just like any other circuit board. It is made to transport signals that travel at lightning speed, typically in the gigahertz. At this speed even the smallest design errors can result in signal loss, noise, or interference. This is why we use specific materials such as PTFE and Rogers laminates rather than standard FR4. These materials assist in maintaining strong, clear signals. It still depends a lot on the traces_layout, spacing and grounding. Every little thing needs to be meticulously thought out by the engineers. FastTurn PCB knows these requirements very well. Working together, their design and manufacturing teams make sure each high frequency PCB is manufactured to precise performance specifications. This in-depth knowledge enables customers to avoid errant decisions and bring better electronic products to market.

Advanced Materials and Precision Manufacturing

High-class Performance The quality of the high frequency PCB is very much dependent on the materials. Suboptimal materials may lead to signal interference and shortened product life. FastTurn PCB will use only the best High frequency laminate materials, and we carry the most popular materials in house. These materials enable signals to move along smoothly without encountering undesirable resistance. The precision manufacturing is also key along with good materials. A little mistake in drilling, laminating or etching ruins the entire board. FastTurn PCB includes latest machines and tools which work to very high-level precision. Their computerized systems need to make each mold line up exactly. This meticulous procedure produces dependable, robust and long-lasting circuit boards. End-users enjoy less EOL, and better device-level performance.

High-Speed Design and Engineering Expertise

Making a high frequency PCB is not simply drawing lines in the computer. It takes a lot of understanding to manage signal flow, impedance control, and thermal properties. A poor design can compromise speed and stability even in small ways. Fast Turn PCB utilizes highly experienced engineers with high speed and RF designs being their speciality. They employ sophisticated computer software that can model and test circuits before they are manufactured. This enables to detect problems in an early stage and saves time as well as money. They and their team also collaborate with clients in order to learn what it is they require from a project. FastTurn PCB offers expert advice to help you with whether it is a basic prototype or a complex multi-layer board. Thanks to their solid engineering, which provides great support for other businesses large and small.

Quality Control and Testing Standards

The quality of high-frequency PCB production is one of the most important factors. Non tested concealed defects can result in a system failure. Standardized quality control is maintained throughout production with FastTurn PCB. Every board is checked for physical damage, misalignment and material impact. Electrical tests are also conducted to verify correct signal flow. State of the art diagnostic tool for checking resistance, impedance and continuity. Environmental tests, meanwhile, assess how a board performs under heat and stress. These procedures help to ensure that every product is in compliance with international standards. With such an emphasis on quality thanks to this procedure, customers can rely on FastTurn PCB for one of a kind and reliable circuit boards.

Fast Turnaround and Customer Support

Time is a valuable commodity in today’s fast-paced market. PCB production delays can postpone projects as a whole. FastTurn PCB has always been famous for fast and efficient delivery. Named as such because of their focus on expediting production without cutting corners in terms of quality. With their efficient processes and state-of-the-art facilities, they can turn around orders fast. Meanwhile, their customer support team are in constant communication with customers. They update, respond and troubleshoot with speed. This kind of clear communication creates strong relationships. FastTurn PCB Whether it is a prototype or mass production, receive consistent and reliable service with FastTurn PCB to keep any businesses competitive.

Conclusion

High-frequency PCB manufacturing is a demanding task. It requires skill, precision, and dedication to quality. The right materials, accurate layouts, and strict testing are crucial, and every aspect makes a difference. However, FastTurn PCB has already proven that it is possible to be a leading company in this sphere. It only takes combining the latest technology to use and knowledge from the best specialists. High standards, fast delivery, and concern about customers make it stand out among others. Companies that need stable and high-speed electronics will especially benefit. FastTurn PCB is a reliable partner for high-frequency PCB. Finally, through innovation and consistency, FastTurn PCB will likely remain at the top of the electronic world for the following several years.