Internationally Recognized Physics Educator Reymond S. Dela Cruz, Ph.D., Advances Inclusive STEM Excellence Across U.S. and Global Education Systems

January 13, 2026How Thomas Wamsley of Aliquippa Is Making a Big Impact for Small Communities?

January 13, 2026

In many industrial environments, safety is not just a priority, it is a necessity. Facilities that handle flammable gases, vapors, or liquids face constant risks of ignition and flame propagation. One small but critical device plays a major role in preventing catastrophic accidents in such systems. That device is the Flame Arrester.

Understanding how flame arresters work, where they are used, and the differences between various types can help engineers, plant managers, and safety professionals make informed decisions. This guide explains the fundamentals of flame arresters, with a clear focus on End of Line Flame Arrester and In Line Flame Arrester designs, their applications, and how to choose the right one for your system.

Understanding the Basic Concept of a Flame Arrester

A flame arrester is a safety device designed to stop the spread of flames through piping, ducts, or vents that carry flammable gases or vapors. It allows normal flow under regular operating conditions but prevents flame transmission if ignition occurs.

The working principle is simple yet highly effective. Inside the arrester, there is a flame-quenching element, often made of metal ribbons, wire mesh, or perforated plates. When a flame front enters the device, heat is absorbed by this element. As the temperature of the flame drops below its ignition point, the flame is extinguished before it can pass through.

This makes flame arresters essential in industries where volatile substances are present and where a single ignition could lead to explosions, equipment damage, or loss of life.

Why Flame Arresters Are Essential in Industrial Systems

Flammable atmospheres are common in sectors such as oil and gas, chemical processing, pharmaceuticals, and wastewater treatment. Even with strict controls, ignition sources can still arise from static electricity, mechanical sparks, or external fires.

A Flame Arrester provides a critical layer of protection by:

- Preventing flame propagation into storage tanks or pipelines

- Reducing the risk of explosions in interconnected systems

- Protecting equipment and infrastructure from fire damage

- Enhancing overall plant safety and regulatory compliance

Without flame arresters, a localized fire could quickly spread through piping systems, turning a small incident into a major disaster.

Common Applications of Flame Arresters

Flame arresters are used in a wide range of industrial and commercial applications. Their placement depends on system design, flow direction, and the type of risk involved.

Typical applications include:

- Vent lines of storage tanks containing flammable liquids

- Gas pipelines and vapor recovery systems

- Chemical reactors and processing units

- Fuel storage facilities

- Biogas and landfill gas systems

In each of these scenarios, the goal is the same: allow safe operation while stopping flames from traveling where they should not.

Key Types of Flame Arresters Explained

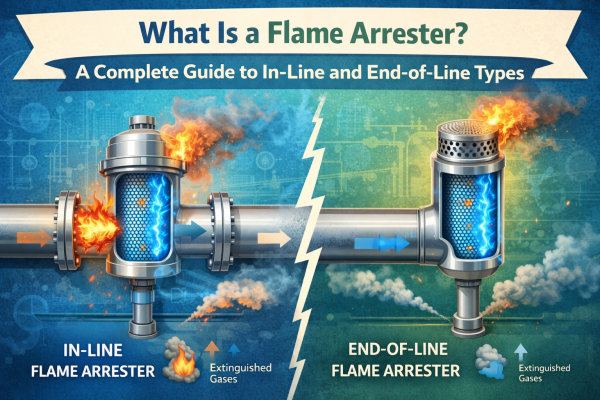

While all flame arresters serve the same fundamental purpose, their design and installation vary based on application needs. The two most common categories are End of Line Flame Arrester and In Line Flame Arrester. Understanding their differences is crucial for selecting the right solution.

What Is an End of Line Flame Arrester?

An End of Line Flame Arrester is installed at the termination point of a vent or exhaust line. It is typically used where flammable vapors are released into the atmosphere, such as on storage tank vents.

This type of arrester prevents an external ignition source from traveling back into the system. For example, if a flame or spark occurs outside the vent opening, the arrester stops it from entering the tank or pipeline.

End of line flame arresters are commonly used in situations where:

- Vapors are vented directly to open air

- There is no continuous flow inside the line

- Protection against flashback is the primary concern

They are often exposed to environmental conditions, so durability and weather resistance are important design considerations.

What Is an In Line Flame Arrester?

An In Line Flame Arrester is installed within a pipeline or duct system, rather than at the end. It is designed to stop flames traveling in either direction, depending on system requirements.

In line flame arresters are used in systems where flammable gases or vapors are continuously flowing between different parts of a facility. If ignition occurs at one point, the arrester prevents the flame from spreading further through the network.

These arresters are ideal for:

- Gas transmission lines

- Vapor recovery systems

- Interconnected processing units

- Systems with bi directional flow risks

Because they are part of the process line, in line flame arresters must be carefully selected to minimize pressure drop while maintaining effective flame quenching.

Differences Between End of Line and In Line Flame Arresters

Although both types serve similar safety functions, their design and usage differ significantly. Understanding these differences helps ensure proper protection and system performance.

Key distinctions include:

- Installation location: End of line units are placed at vent exits, while in line units are installed within piping systems.

- Flow conditions: End of line arresters often handle intermittent or low flow, while in line arresters manage continuous flow.

- Protection focus: End of line arresters primarily stop flashback from external sources, while in line arresters prevent flame spread within the system.

- Maintenance needs: In line arresters may require more frequent inspection due to continuous exposure to process media.

Selecting the wrong type can lead to reduced efficiency, higher maintenance costs, or compromised safety.

How Flame Arresters Are Designed and Tested

The effectiveness of a Flame Arrester depends heavily on its internal design and compliance with industry standards. Manufacturers design flame arresters based on factors such as gas group, maximum operating pressure, and temperature limits.

Key design considerations include:

- Flame path length and gap size

- Material selection for corrosion and heat resistance

- Ease of cleaning and inspection

- Compatibility with specific gases or vapors

Flame arresters are tested under controlled conditions to ensure they can stop flames under defined scenarios. These tests simulate deflagrations and flashback events to verify performance.

Installation Best Practices for Flame Arresters

Proper installation is just as important as choosing the right device. Incorrect placement or poor installation can reduce effectiveness or cause operational issues.

Best practices include:

- Installing the arrester as close as possible to the potential ignition source

- Ensuring correct orientation based on flow direction

- Providing adequate support to avoid vibration or stress

- Allowing access for inspection and maintenance

It is also important to follow manufacturer guidelines and applicable safety codes when installing flame arresters.

Maintenance and Inspection Considerations

Like any safety device, flame arresters require regular inspection and maintenance to remain effective. Over time, debris, corrosion, or process residues can clog the flame element, increasing pressure drop or reducing flame-quenching ability.

A good maintenance program should include:

- Routine visual inspections

- Periodic cleaning of flame elements

- Checking for corrosion or mechanical damage

- Verifying compliance with safety standards

Neglecting maintenance can turn a flame arrester into a flow restriction rather than a safety asset.

Choosing the Right Flame Arrester for Your System

Selecting the appropriate Flame Arrester involves evaluating several system-specific factors. There is no one-size-fits-all solution, so careful assessment is essential.

Important selection criteria include:

- Type of flammable gas or vapor

- Operating pressure and temperature

- Flow rate and direction

- Installation location

- Environmental exposure

Consulting with experienced suppliers or safety engineers can help ensure that the chosen End of Line Flame Arrester or In Line Flame Arrester meets both safety and operational requirements.

Final Thoughts on Safe and Reliable Flame Control

Flame arresters may appear simple, but their role in industrial safety is critical. By stopping flames before they spread, they protect lives, equipment, and entire facilities from devastating incidents.

Understanding how different flame arresters work, where they should be installed, and how they should be maintained allows organizations to build safer and more reliable systems. Whether you are dealing with tank venting or complex pipeline networks, choosing the right flame arrester is an investment in long-term safety and operational stability.

With the right knowledge and careful selection, flame arresters become silent guardians, working in the background to keep hazardous processes under control every day.